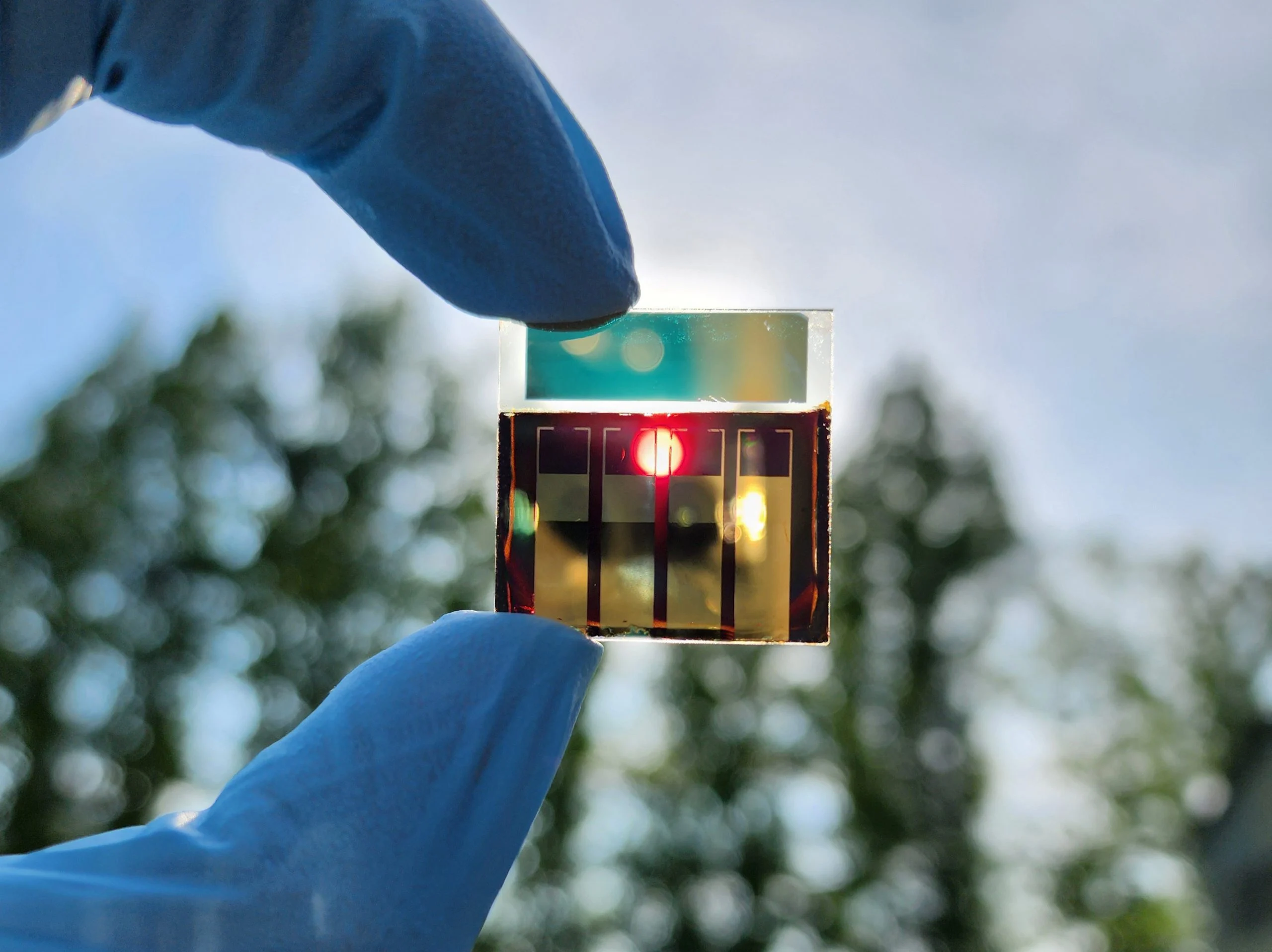

Scientists at the Korea Institute of Energy Research (KIER) have achieved a major milestone in solar technology by developing a flexible CIGS (copper indium gallium selenide) solar cell using ultra-thin glass (UTG). This emerging substrate is known for its superior flexibility and stability, which makes it ideal for various non-flat applications. With a record-breaking efficiency of over 17% for cadmium-free cells, the innovation demonstrates a successful balance between high performance and mechanical durability.

Advanced Fabrication Techniques Enhance Flexibility, Performance, and Sustainability of Solar Cells

To construct the solar cell, researchers utilized 90 μm-thick UTG supplied by South Korea’s Unique Technology Integral (UTI). They applied molybdenum (Mo) back contacts using DC magnetron sputtering, followed by the addition of silver (Ag) layers. A crucial part of the process was a three-stage co-evaporation to deposit a 2.0 µm-thick CIGS absorber, which was later enhanced with sodium (Na) and rubidium (Rb) post-deposition treatments to improve cell performance.

Korean Scientists Develop Record-Efficient Flexible Solar Cells Using Ultra-Thin Glass and Eco-Friendly Materials

The team replaced the traditional cadmium sulfide (CdS) buffer layer with an environmentally friendly mix of zinc oxide (ZnO) and magnesium oxide (MgO), maintaining efficiency while avoiding toxic materials. A thin Ag precursor layer also aided in grain growth and protected the cell during the low-temperature fabrication process. These changes not only maintained device integrity but also supported flexibility, a key requirement for UTG-based solar cells.

Achieving High Efficiency and Commercial Scalability for Flexible, Eco-Friendly Solar Technologies

Under standard testing conditions, the solar cell reached a power conversion efficiency of 17.81%, comparable to CdS-based cells. Larger 60 cm² modules built with the same process showed efficiencies above 10%, suggesting strong potential for commercial scalability. The successful integration of silver with UTG at lower processing temperatures proves critical in expanding the practical application of flexible solar technologies.

Published in the Journal of Alloys and Compounds, the study underlines significant progress toward sustainable, high-performance solar energy solutions. These flexible, cadmium-free solar cells are not only eco-friendly but also ideal for integration into wearable electronics, electric vehicles, and curved surfaces. Furthermore, their use as bottom cells in tandem configurations with perovskite solar cells opens new possibilities for even greater solar efficiency in future devices.